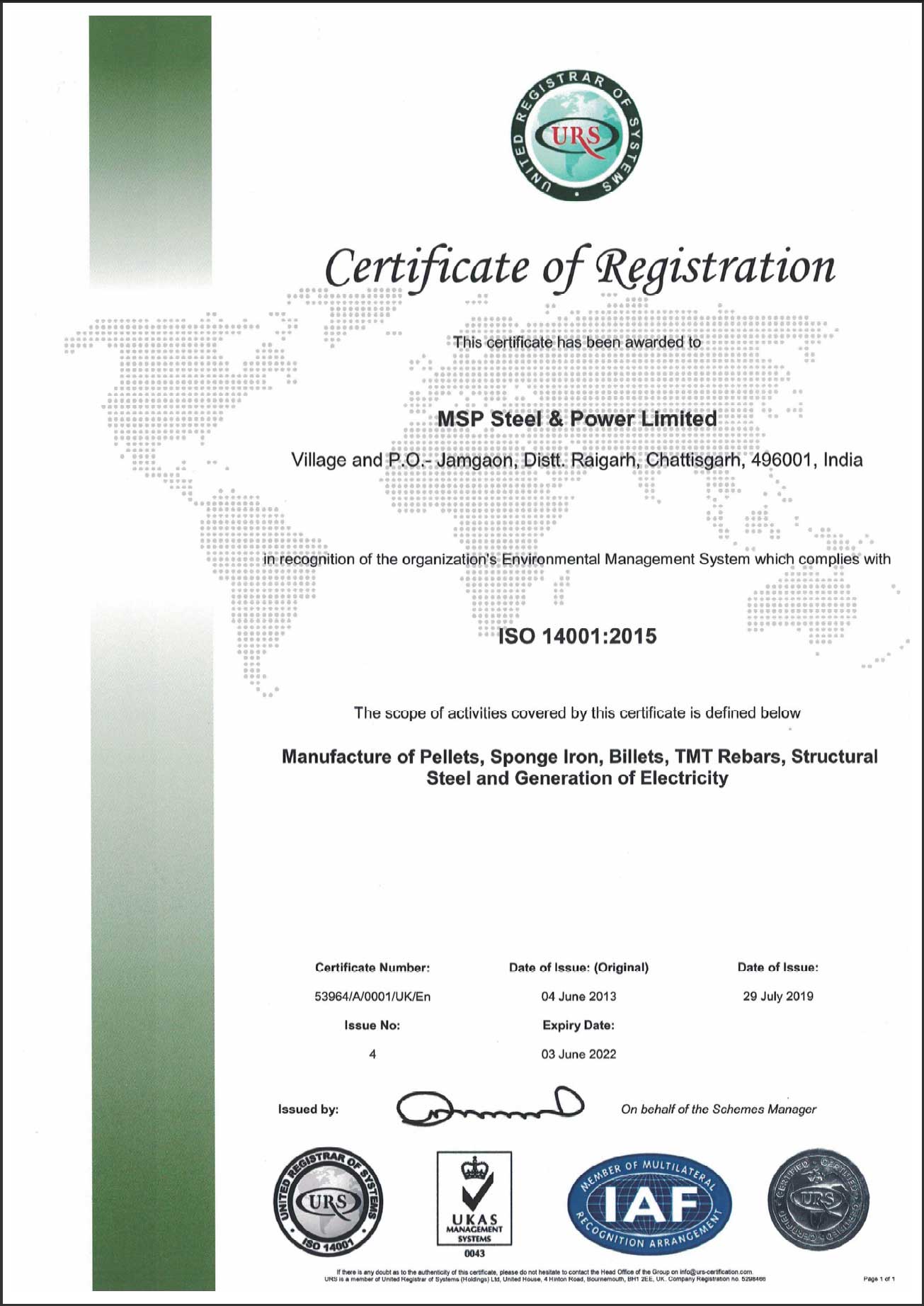

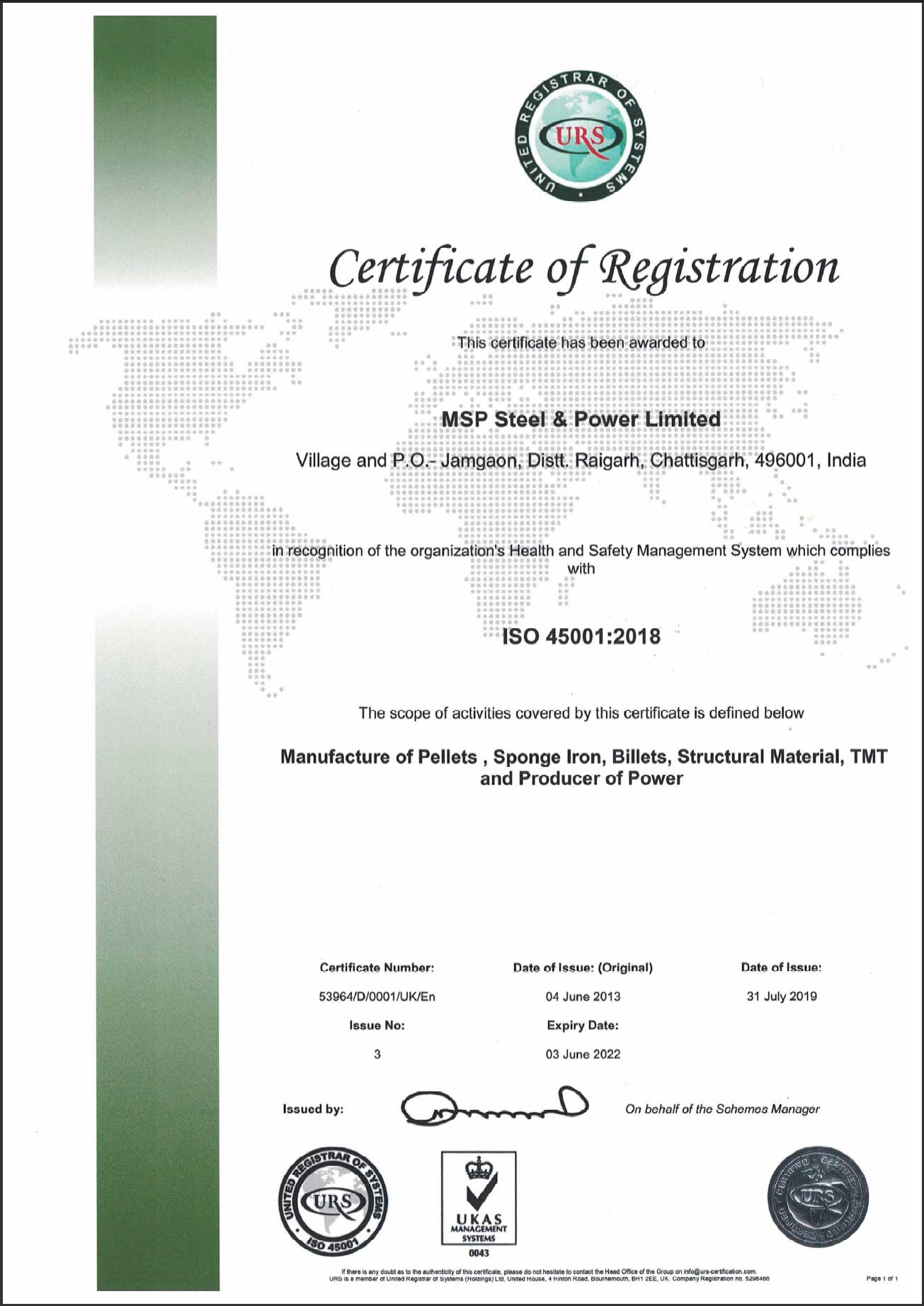

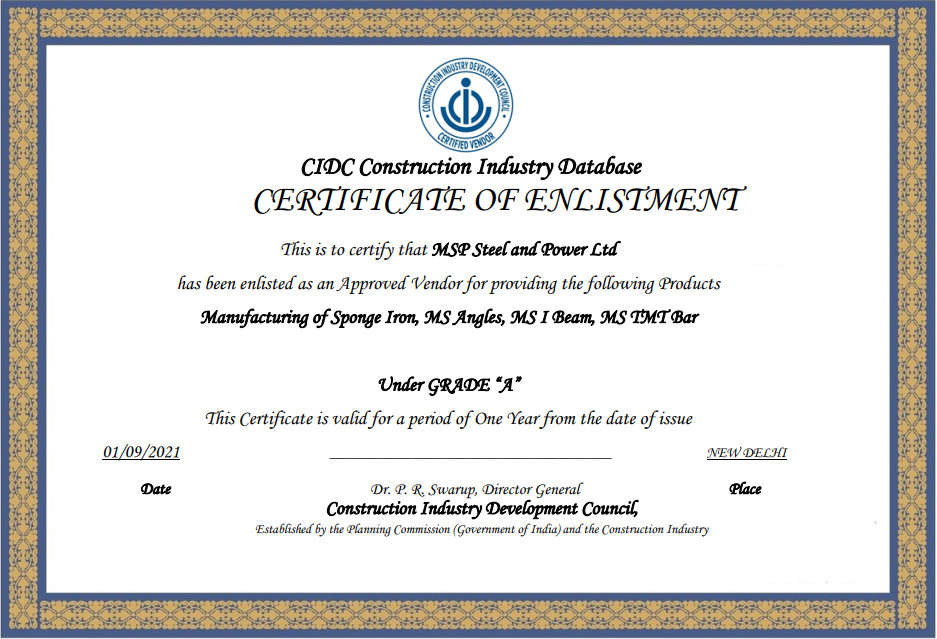

Steel fabrication, at its core, is a manufacturing process that transforms raw or semi-finished materials into a finished item, distinct from simply assembling pre-made components. In the realm of structural steel, this process is fundamental to creating essential infrastructure such as bridges, buildings, and even furniture from various steel sections like angles, beams, channels, and plates. A crucial aspect of steel fabrication is the subsequent erection of the structure, which ensures that the desired geometry and stress-bearing capacity are achieved under full load and temperature conditions as per design specifications. Companies like MSP Steel and Power Limited, an integrated steel manufacturer with its plant in Raigarh, Chhattisgarh, exemplify this comprehensive approach, producing a wide range of steel products that serve as the backbone for numerous construction and industrial projects across India.

Generally, steel fabrication follows two primary procedures: rigorous shop fabrication conducted under strict quality control, and on-site fabrication and erection. This dual approach highlights the complexity of steelwork fabrication, demanding extensive expertise in material selection, fabrication systems, and erection methodologies to ensure the structural integrity and longevity of the final product.

Fabrication Process and Technology

The steel fabrication industry is fundamentally centered around two main activities: precisely cutting primary steel sections into required sizes according to design drawings, and then expertly joining these pieces to form the desired structures or assemblies. Steel can be utilized in either hot-rolled or cold-processed forms. Before any cutting commences, incoming steel from manufacturers, such as billets and structural sections from MSP Steel's integrated plant, undergoes a thorough inspection to ensure its quality and adherence to designer specifications, both in terms of quantity and material properties. After the joining process, which constitutes the core of fabrication, the finished steel structures or assemblies are typically painted. This painting is considered an integral part of fabrication activities, as it significantly enhances the service life of the steel by providing protection against corrosion and other environmental factors.

While it is advisable to carry out most fabrication activities within a workshop setting due to controlled conditions, some activities may indeed be performed on-site (on-site fabrication). In essence, steel fabrication involves a network of parallel activities that collectively contribute to the efficient and timely completion of any project.

The equipment and machinery employed in the fabrication industry are continuously being upgraded to improve quality and expedite the fabrication process. However, the substantial cost of most new equipment and the considerable lead-time required to bring it into operation mean that changes in production methods and product offerings are adopted gradually. Even groundbreaking new processes or technologies that could fundamentally alter the industry are typically integrated over extended periods.

Cutting Operations: Precision in Material Removal

In steel fabrication, cutting operations are fundamental processes for transforming raw or semi-finished steel into precise shapes and sizes. These techniques are designed to create specific geometries, including holes, openings, blanks, or custom parts, by material separation. The selection of a particular cutting method depends on factors such as the material's thickness, desired precision, production volume, and the complexity of the shape. Manufacturers like MSP Steel, which produce a wide array of structural products including H-beams, I-beams, channels, angles, and round bars, utilize these advanced cutting operations to prepare their materials for downstream fabrication into various structural components.

- Punching: This is a high-speed hole-making operation where a specially shaped punch is driven through the steel sheet or plate into a corresponding die. The material is separated by shear stress, creating a clean hole and typically producing a slug (the removed material) that is often discarded. Punching is highly efficient for producing numerous holes, especially in thinner gauges of steel, and can be automated for mass production. Tooling design, including punch-to-die clearance, is critical for achieving clean cuts and minimizing burr formation.

- Piercing: Mechanically similar to punching, piercing involves creating an initial hole in a workpiece. The key distinction often lies in the purpose: in piercing, the primary objective is to create an opening, and the removed slug is usually considered waste. This operation is often a precursor to other processes like forming or internal cutting operations, providing a starting point for subsequent material removal.

- Blanking: Unlike punching where the slug is the waste, in blanking, the objective is to cut a specific, desired shape (the "blank") from a larger sheet of material. The material surrounding the blank is typically considered scrap. Blanking is widely used to produce flat components with precise outer contours, serving as the starting point for parts that may undergo further forming, machining, or assembly. The accuracy of the blanking die is crucial for maintaining dimensional tolerances.

- Cutting-off: This is a broad term for operations designed to separate a section from a longer piece of stock, such as a bar, tube, or structural profile. This can be achieved through various methods, including sawing, shearing, or abrasive cutting, depending on the material's cross-section and the required finish. The primary goal is to produce discrete pieces of a specified length.

- Parting: Often used interchangeably with cutting-off, parting specifically refers to the process of separating multiple finished parts from a single, continuous piece of stock, usually in a sequential manner. This is common in automated production lines where a long bar or coil is incrementally cut into numerous identical components. Precision and repeatability are paramount in parting operations to ensure consistent part length.

- Shearing: This linear cutting operation involves separating material, typically sheet metal or plate, between two opposing blades. One blade is fixed, and the other moves past it with a small clearance, causing the material to fracture and separate due to shear forces. Shearing is a highly efficient method for cutting straight lines and is commonly used for preparing stock for subsequent fabrication steps. Factors like blade angle, blade gap, and back gauge settings significantly influence the quality of the cut and minimize distortion.

- Trimming: Trimming is a finishing operation focused on removing excess material from the edges or periphery of a part that has already undergone a primary cutting or forming process. This is often necessary to remove irregular edges, flash (excess material squeezed out during forming), or to achieve precise final dimensions and a clean edge finish. Trimming enhances both the aesthetic appeal and the functional fit of the fabricated component.

These cutting operations, whether performed manually, semi-automatically, or through advanced CNC (Computer Numerical Control) systems, form the foundation of steel fabrication, enabling the precise shaping of metal to meet rigorous engineering specifications.

Forming Operations: Shaping Steel Without Material Removal

Forming operations are critical processes in steel fabrication that sculpt steel sections into desired configurations by inducing plastic deformation, meaning the material's geometry is permanently altered without any significant material removal. These techniques leverage the steel's ductility to achieve complex shapes, producing both two-dimensional and three-dimensional components essential for various structural applications. The choice of forming process depends on the desired shape, the mechanical properties of the steel, and the scale of production. MSP Steel's range of structural products, including various sections and TMT bars, highlights the versatility achieved through these precise forming methods, meeting BIS certified quality standards for diverse industrial, infrastructural, and agricultural sectors.

- Bending: Often considered the most fundamental forming operation, bending involves applying a moment or force to a steel section, causing it to deform plastically along a linear axis. This results in the creation of a specific angle or curved profile. Common methods include press brake bending (using a punch and die), roll bending (for large radius curves), and rotary draw bending (for precise tube and pipe bends). The springback of the steel, which is its tendency to partially return to its original shape after bending, must be accounted for in tooling design and process parameters.

- Twisting: This operation involves deforming a steel section by applying a torsional load (torque) along its longitudinal axis. This induces a helical deformation, resulting in a twisted shape. Twisting is used to achieve specific aesthetic designs, improve structural rigidity in certain applications, or to align features in a multi-axis component. The degree of twist can be precisely controlled, making it valuable for architectural elements or specialized structural members.

- Extruding: In extrusion, a heated (or sometimes cold) steel billet is forced through a shaped die opening under high pressure. This process reduces the cross-section of the material and produces a continuous length of uniform cross-section, which can then be cut to desired lengths. Extrusion is highly efficient for producing complex solid or hollow profiles, such as angles, channels, or custom shapes, that would be difficult or impossible to achieve through rolling or other methods. It imparts a high degree of dimensional accuracy and an excellent surface finish.

- Drawing: This operation involves pulling a metal blank or workpiece through a die to alter its cross-sectional area or shape. Wire drawing reduces the diameter of a wire, while deep drawing is used to create hollow, cup-shaped, or box-shaped components from flat sheet metal, such as sinks or automotive parts. The material is elongated and thinned as it is drawn, increasing its strength through strain hardening. Careful lubrication and multi-stage drawing might be necessary for complex shapes.

- Rolling: Rolling is a primary metal forming process where steel stock is passed between a pair of rotating cylindrical rolls. The compressive forces exerted by the rolls reduce the thickness of the material and/or change its cross-sectional shape. Hot rolling is common for producing large sections like beams, channels, and plates from ingots, while cold rolling is used for thinner sheets and strips, offering superior surface finish and tighter dimensional tolerances. Rolling is a continuous process fundamental to producing the foundational forms of steel used in fabrication, including the structural sections manufactured by companies like MSP Steel.

- Spinning: Primarily used for forming symmetrical, hollow, and often conical or cylindrical parts from flat sheet metal. In spinning, a sheet metal blank is rotated at high speed while a forming tool (often a roller) progressively pushes the material against a rotating mandrel (a form or mold). This process gradually deforms the blank into the desired shape. Spinning is economical for low to medium volume production and allows for considerable material flexibility in terms of shape complexity.

- Coining: A specialized closed-die forging process that involves applying high compressive forces to a metal blank within a die cavity. The material is plastically deformed to fill the die, producing a very precise impression on the surface of the part, often with intricate details. Unlike general forging, coining is characterized by minimal material flow and is typically used for creating sharp, precise features on surfaces, such as those found on coins or medallions, or for achieving very tight dimensional tolerances on certain components.

- Forging: This involves shaping metal by applying localized compressive forces using hammers (in impact forging) or presses (in press forging). Forging can be performed hot or cold. Hot forging is common for larger, more complex shapes, as it reduces the material's yield strength and increases ductility, allowing for significant deformation. Cold forging provides higher strength and better surface finish. Forging refines the grain structure of the steel, leading to improved mechanical properties such as increased strength, toughness, and fatigue resistance, making forged components ideal for high-stress applications like crankshafts or connecting rods.

These diverse forming operations are pivotal in tailoring steel's raw forms into the precise and robust components demanded by the structural and mechanical engineering sectors, showcasing the versatility and adaptability of steel as a construction material.

Machining: Achieving Precision and Surface Integrity in Steel Fabrication

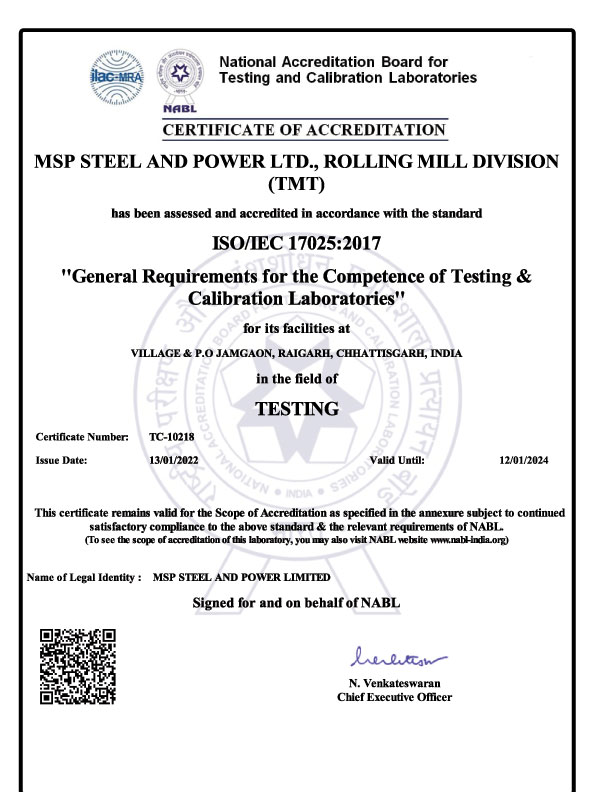

Machining in the context of steel fabrication represents a suite of subtractive manufacturing processes critical for achieving tight dimensional tolerances, superior surface finishes, and precise geometric features that cannot be attained through initial shearing, forming, or welding operations alone. This stage involves the meticulous removal of unwanted material, often in the form of chips, from various parts of the steel workpiece, including joints, edges, and internal sections. Machining tasks are inherently technically demanding, necessitating highly trained personnel with a deep understanding of material science, cutting mechanics, and machine operation, along with the deployment of appropriate, often specialized, machine tools. Quality control, a key aspect in companies like MSP Steel which maintains NABL certified testing facilities at its integrated steel plant, ensures that machined components meet rigorous BIS (Bureau of Indian Standards) specifications for applications ranging from general engineering to large-scale industrial structures.

- Drilling: This is a fundamental machining operation used to create circular holes in solid materials. A rotating cutting tool, known as a drill bit (typically helical), is fed axially into the workpiece, progressively removing material to form a through-hole or a blind hole. The size and type of drill bit, along with parameters like cutting speed and feed rate, are critical for achieving accurate hole diameters, desired surface finish, and efficient chip evacuation. Drilling is often a preparatory step for other operations like tapping (threading) or reaming (sizing and improving hole finish).

- Milling: A versatile machining process that involves removing material using a rotating multi-point cutter. The workpiece is typically held stationary or moved against the rotating cutter. Milling operations can create a vast array of features, including flat surfaces, slots, grooves, steps, pockets, and complex three-dimensional contours. Depending on the relative motion between the cutter and the workpiece, milling can be categorized into face milling (for flat surfaces), peripheral milling (for creating slots or side surfaces), and profile milling (for following intricate shapes). Modern CNC milling machines offer exceptional precision and automation for complex part geometries.

- Turning: This is a machining process performed on a lathe, primarily used to create cylindrical or conical shapes. The workpiece rotates at high speed, while a single-point cutting tool is fed linearly along its axis or radially towards it, removing material from the outer diameter (turning) or inner diameter (boring). Turning can produce a wide range of features such as steps, tapers, threads, and contours. It is crucial for manufacturing shafts, pins, bushings, and other rotationally symmetric components.

- Shaping/Planning: These are traditional machining processes that create flat or contoured surfaces by employing a reciprocating single-point cutting tool. In shaping, the cutting tool moves back and forth across a stationary workpiece. In planning, the workpiece reciprocates past a stationary tool. While slower than milling, shaping and planning are effective for machining large, flat surfaces or creating specific linear features, especially in heavy fabrication where robust material removal is required. They are less common in modern high-volume production but still valuable for certain heavy-duty applications or specific geometries.

- Broaching: A highly efficient machining process that utilizes a multi-tooth tool, known as a broach, to remove material in a single pass. Each successive tooth on the broach is slightly larger than the previous one, progressively removing more material as the tool is pulled or pushed across the workpiece. Broaching is ideal for creating complex internal or external shapes, such as keyways, splines, or non-circular holes, with high precision and excellent surface finish in a short cycle time.

- Sawing: This is a fundamental cutting operation used for separating steel sections or cutting off excess material using a saw blade. Sawing can be performed using various types of saws, including bandsaws (continuous blade for straight or contoured cuts), circular saws (rotating disc blade for straight cuts), and hacksaws (reciprocating blade). Sawing is often the initial material reduction step before more precise machining operations, or for cutting structural members to length in preparation for welding or assembly.

- Grinding: A finishing operation that utilizes an abrasive wheel composed of numerous small abrasive particles bonded together. Grinding is employed to remove small amounts of material, achieve extremely tight dimensional tolerances, and produce superior surface finishes that are smooth and free of defects. It is often the final machining step for components requiring high precision, such as bearing surfaces, gears, or cutting tools. Various grinding methods exist, including surface grinding (for flat surfaces), cylindrical grinding (for external cylindrical surfaces), and internal grinding (for internal cylindrical surfaces).

In essence, machining operations elevate the precision and functional quality of fabricated steel components. They are indispensable for meeting the stringent requirements of modern engineering, ensuring that fabricated structures and machinery perform reliably under diverse operational conditions.

Conclusion: The Backbone of Modern Infrastructure

Steel fabrication stands as a sophisticated and indispensable industry, weaving together a complex tapestry of specialized processes. From the initial meticulous material inspection and precise cutting operations that define raw steel's first transformation, through the intricate stages of forming that sculpt its shape without material loss, and the critical joining techniques that unite disparate components, to the final, highly accurate precision machining that refines and perfects the finished product—each step is vital. This integrated approach, exemplified by companies like MSP Steel and Power Limited, which contribute to the nation's core infrastructure by producing quality structural steel sections and PREMIUM TMT bars, culminates in the creation of robust and precisely engineered steel structures that are the very foundation of modern infrastructure. The seamless orchestration of these diverse skills and technologies ensures the integrity, longevity, and functionality of everything from towering skyscrapers and expansive bridges to intricate machinery and essential furniture, solidifying steel fabrication's pivotal role in shaping our built environment.